Contact Today!

+90 212 549 0275

Contact Today!

+90 212 549 0275

Top Class Materials for the Best Results. We are working with reliable partners and high-grade raw materials, which is the foundation of our quality standarts. We have a well-stocked warehouse with a wide variety of raw materials in varying diameters. This enables us the possibility to start manufacturing at a very short notice when the need arises.

| Material Category | Material Examples |

|---|---|

| Aluminum and its alloys | AlMgSi1, AlCuMgPb, AlZnMgCu0 |

| Free cutting steels | 9SMnPb28, 11SMn30 |

| Structural steel and tempered steels | C35, C45, St37, St52 |

| Case-hardened steel | 16MnCrS5, 42CrMo4 |

| Corrosion and heat resistant materials | Hastelloy, Inconel, Nimonic |

| Plastics | PA, PE, PEEK, POM, PTFE, PVC |

| Copper-based | E-CU, Cu-Be, brass, bronze, nickelsilver |

| Pure metals | nickel, molybdenum |

| Corrosion and acid resistant steels | 1.4301, 1.4305, 1.4307, 1.4401, 1.4435, 1.4546, 1.4548, 1.4571 |

| Rolling bearing steel | 100Cr6, 115CrV3 |

| Tool steel | 1.2083, 1.2842 |

| Material standard | Germany (DE) DIN | France (FR) AFNOR NF | UK B.S. | Spain (ES) UNE |

|---|---|---|---|---|

| 1.0402 | C22 | XC 25 | 070M20 | F.112 |

| 1.0503 | C45 | XC 45 | 080M46 | F.114 |

| 1.0715 | 11SMn30+C | - | 230M07 | F.2111 |

| 1.0718 | 11SMnPb30+C | S250Pb | - | F.2112 |

| 1.3505 | 100Cr6 | 100Cr6 | 25135 | F.1310 |

| 1.4006 | X12Cr13 | Z10C13 | 410C21 | F.3401 |

| 1.4021 | X20Cr13 | Z10C13 | 420S37 | F.3402 |

| 1.4028 | - | - | 420S45 | F.3403 |

| 1.4034 | X46Cr13 | Z44C14 | - | F.3405 |

| 1.4057 | X17CrNi16-2 | Z15CN16-02 | 431S29 | F.3427 |

| 1.4104 | X14CrMoS17 | Z13CF17 | - | F.3117 |

| 1.4125 | X105CrMo17 | Z100CD17 | - | - |

| 1.4301 | X5CrNi1810 | Z4CN19-10FF | 304S17 | F.3541 |

| 1.4305 | X8CrNiS18-9 | Z8CNF18-09 | 303S22 | F.3508 |

| 1.4401 | X5CrNiMo17122 | Z6CND17-11 | 316S17 | F.3543 |

| 1.4404 | X2CrNiMo17132 | Z3CND18.12.02 | 316S11 | F.3533 |

| 1.4462 | X2CrNiMoN22-5-3 | Z2CND17-12 | 318S13 | - |

| 1.4571 | X6CrNiMoTi17-12-2 | Z6CNDT17-12 | 320s18 | F.3535 |

| 1.7225 | 42CrMo4 | 42CrMo4 | 708M40 | F.1252 |

| 2.0561 | CuZn40Al1 | - | - | - |

| 2.1030 | CuSn8 | - | - | - |

| Material standard | Sweden (SE)SS14 | Italy (IT) UNI | USA SAE/AISI | Czech Rep. (CZ) CSN | Type |

|---|---|---|---|---|---|

| 1.0402 | 1450 | C21 | M 1023 | 41 2024 (1984) | 12024 |

| 1.0503 | 1650 | C45 | Aisi 1043 | 41 2050 (1976) | 12050 |

| 1.0715 | - | - | - | 41 1109 (1974) | 11109 |

| 1.0718 | 1914 | CF9SMnPb28 | 12L13 | - | - |

| 1.3505 | 2258 | 100Cr6 | Aisi 52100 | 41 4109 (1976) | 14109 |

| 1.4006 | 2302 | X10Cr13 | Aisi 410 | 41 7021 (1980) | 17021 |

| 1.4021 | 2303 | X20Cr13 | Aisi 420 | - | - |

| 1.4028 | - | - | - | 41 7023 (1976) | 17023 |

| 1.4034 | - | X40Cr14 | - | - | - |

| 1.4057 | 2321 | X16CrNi16 | Aisi 431 | - | - |

| 1.4104 | 2383 | X10CrS17 | Aisi 430F | - | - |

| 1.4125 | - | - | Aisi 440C | - | - |

| 1.4301 | 2332 | X5CrNi1810 | Aisi 304 | 41 7240 (1972) | 17240 |

| 1.4305 | 2346 | X10CrNiS1809 | Aisi 303 | - | - |

| 1.4401 | 2347 | X5CrNiMo1712 | Aisi 316 | 41 7646 (1972) | 17240 |

| 1.4404 | 2348 | X2CrNiMo1712 | Aisi 316L | - | - |

| 1.4462 | 2377 | - | Aisi 318LN | - | - |

| 1.4571 | 2350 | X6CrNiMoTi1712 | Aisi 316Ti | - | - |

| 1.7225 | 2244 | 42CrMo4 | Aisi 4140 | 41 5142 (1977) | 15142 |

| 2.1030 | - | - | - | - | - |

| 2.0561 | - | - | - | - | - |

We can always help you more than just manufacturing your components. We also have rigid processing and finishing steps which we carry out exactly to your demands and specifications. With the help of our wellestablished knowhow, we are more than happy to advise you on your material and finishing procedure choice which will best suit your needs. Please do not hesitate to contact us

Our range of services does not only concern manufacturing of your components. In order to supply our customers with parts which are truly ready for fitting, we also dedicate ourselves to secondary processing and finishing procedures precisely according to your requests. This is what makes us stand out as an innovative partner and supplier. Our range of services does not only concern manufacturing of your components. We are also dedicated to secondary processing and finishing procedures that fit your requests. At the end of the day, we will always stand out as your innovative partner and supplier. In this point, what differentiates us is that we are always in close cooperation with our longstanding suppliers and we can virtually do anything that they require from us. All you have to do is to let us know your requirements and we will find an appropriate solution.

When the need arises, finishing treatments are provided in our conventional workshop in a wellequipped station. Here the parts are processed or finished on the sides with high precision. In this stage, we can manufacture complex components in small to big volumes. Finishing operations are performed with great attention to throughfeed, flat grinding and to centerlessness. These procedures require an extensive technical expertise and knowhow. And we always meet high standards for dimensional shape, surface finish and tolerances with the help our monitored machinery. {

Thanks to the Proper Finishing Touches, Always Ready Precision Parts for Fitting

Tumble finishing and vibratory finishing enable us to reach a great level of vertical manufacturing in our processes. The result is always defectfree parts and – if there is the need – a bright surface.

This is the last phase of our production in whicn we clean and degrease all the manufactured parts in our hightech cleaning machine in a closed system. at the End of the process, with the help of specific programs, we oil the manufactured parts. Upon need and request, we can ask our partners finish the components. Finally we can package and deliver the components ready for fitting in a protected manner from corrosion and to be stocked by our customers

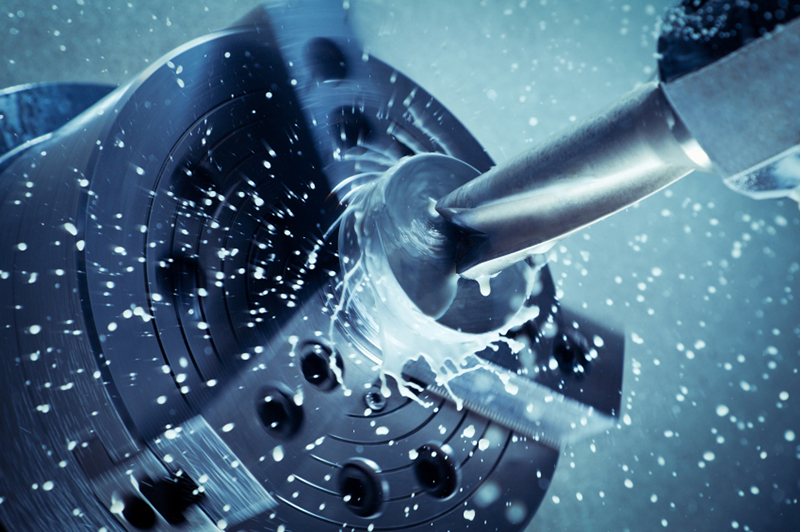

In our production, we apply the most modern machinery in the industry which let us react to our customers always with precision, speed, flexibility and experience.We help them meet their challenges by meeting their rigorous delivery deadlines.

Our manufacturing philosophy is to offer our customers the necessary flexibility for their demands. However challenging their demands are, we always try to offer a balanced performance/price ratio. In doing all this, we always execute an highly efficient workflow with the quickest communication times.

Huge list of standard components with cutting-edge technology and thorough monitoring of production.

Thousands of tested top-quality turned parts and subassemblies for your special applications.

Need more than a standard linking element? Tailored and innovative advice on your special requirements.